Ron Kool, executive vice president at ASML, doesn’t expect the increased demand for fast chips to shrink back to pre-Covid levels. Both the computer and automotive industries are currently facing tightness due to tremendously high demand.

“I think all over the place…the demand to our customers — so the semiconductor manufacturers — I would say that all over the place you see a stressful situation”, Ron Kool, an executive vice president at ASML, told Reuters. According to Kool, the increased demand is a lot higher than the industry expected at the beginning of the corona crisis. ASML is also said to have underestimated the demand.

“For me personally, I don’t think it’s a wave”, Kool said. “I think we’ve come to a new level, that’s my view.” Kool refers not only to the increased demand for computers by people working from home but also to new applications such as 5G telecommunications, cars, data centres, industrial electronics and IoT devices.

The automotive industry in particular is facing severe shortages. Various manufacturers have already had to shut down production lines because there simply were not enough parts to finish the cars. Shortages are also becoming increasingly acute in other markets. AMD and Nvidia can barely keep up with the demand for their chips. Chip manufacturer Samsung Electronics said in January that the chip shortage could also affect the availability of chips for smartphones.

The struggle to increase production

Various parties are working hard on solutions for the shortages. In the long term, these solutions mainly involve increasing the production of microchips. This requires the construction of new factories, which takes several years. Both the United States and Europe are working hard to persuade companies such as Samsung and TSMC to build new factories in territories. In this way, the superpowers hope to become less dependent on China, where most new chip factories are currently being built, but tensions are rising.

ASML’s EUV

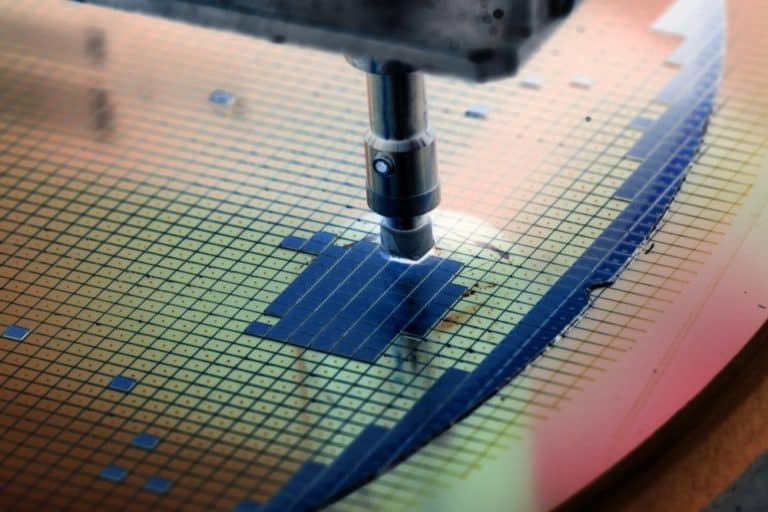

Samsung and TSMC are heavily dependent on the Dutch company ASML for the construction of new factories. ASML builds the machines that are used for chip production. With the latest ‘Extreme Ultraviolet’ (EUV) techniques, it is possible to make smaller chips. However, the machines for this are very expensive and producing chips is very laborious. Intel has therefore been struggling for several years to reduce its production process, and Global Foundries recently announced that it was dropping out of the race for increasingly small chips.