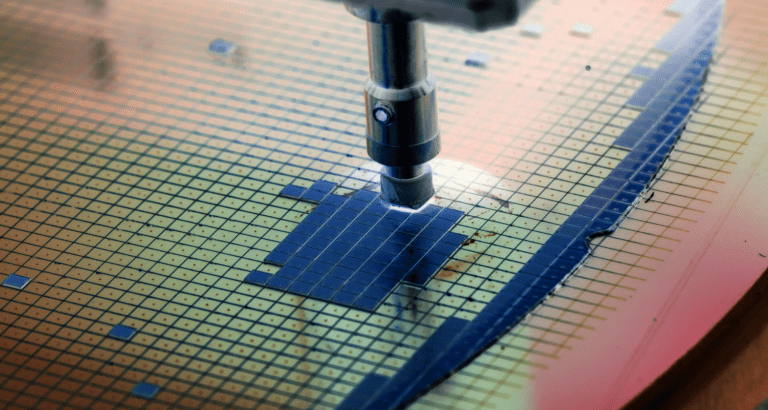

The demand for chips skyrocketed during the pandemic. However, this global demand has made it extremely difficult for the suppliers to keep up.

With almost every company relying on other manufacturers in a never-ending chain of dependency, with an aim to create a functional operation to provide consumers with the technology they desire, the supply chain is a complex cycle. The demand for silicon increased during the pandemic, leading to product disruptions in the supply chain and global shortages.

For some time, chipmakers were blamed for the shortage. However, the game of blame has taken much deeper roots. As revealed in the latest report, the manufacturers supposedly make machinery parts for chipmakers putting off the operations. Nikkei Asia reported that “Leading chip tool makers – including Applied Material, Lam Research, KLA, and ASML – are alerting the client that they are most likely to wait up to 18 months for some crucial machines.”

The issue at hand

Allegedly a huge range of parts required for making chip-making machinery aren’t in huge supply, including lenses, electronic modules, and valves. And it keeps getting worse.

The delivery time for components in shortage has gotten worst since 2020. The approx. delivery date in 2019 for supplies like these was around three to four months.

However, in 2021, this delivery time escalated to 10-12 months. These are being referred to as the “worst (delays) in decades.” The number of equipment parts for testing even has a delivery time of 30-months. This seems to indicate that the general expectation in the market that the supply chain will have decreased considerably by the end of 2022, may be a bit too positive.