A third (32%) of the expected global semiconductor production worth US$1 trillion is at risk within ten years if the sector does not adapt to climate change. This is according to a new report by PwC.

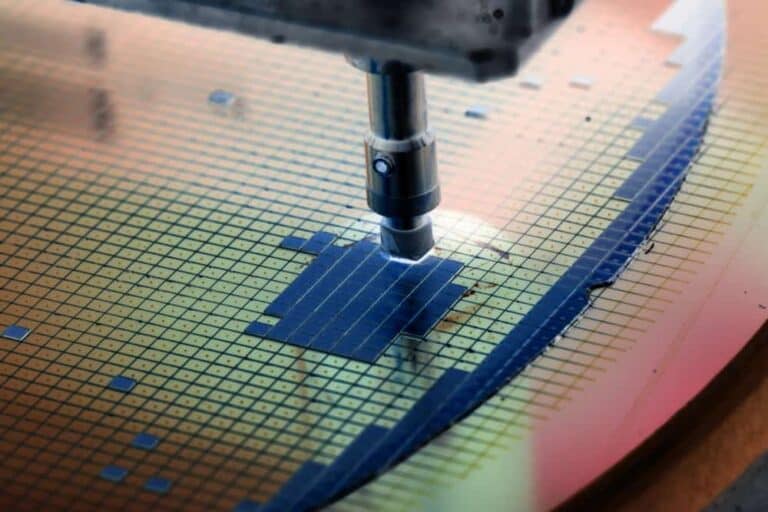

Climate change could disrupt semiconductor production, partly because copper is becoming increasingly vulnerable to extreme weather conditions and drought. Semiconductors are a crucial component of the modern digital economy. The global semiconductor industry is expected to reach a value of US$1 trillion by 2030.

According to PwC’s analysis, by 2035, approximately 32% of global semiconductor production is expected to rely on a copper supply that is vulnerable to disruption due to climate change. If greenhouse gas emissions are not reduced, that share is projected to rise to 58% by 2050. The risks are growing rapidly, underscoring the importance for companies to identify and manage hidden vulnerabilities in their supply chains on time.

Stable water supply essential

Copper mines require a stable water supply to operate effectively. However, increasing drought due to climate change is putting them at greater risk of disruption. This development poses a growing threat to both copper-exporting countries and the companies that use it in the production of semiconductors. If no action is taken, supplies could be seriously disrupted.

According to Glenn Burm, head of PwC’s global semiconductor division in South Korea, semiconductors are indispensable for virtually all modern technologies. They are in everything, from computers and phones to cars and household appliances. They are essential for economic stability, form the basis for the development of artificial intelligence, and play a key role in the transition to renewable energy. Burm emphasizes that companies worldwide are already taking steps to adapt, for example by improving their water supply, seeking alternative suppliers, and increasing their resilience to climate disruption. But he believes that companies need to do more, especially as dependence on critical raw materials continues to grow due to the digital transformation.

At present, only Chile is at high risk of drought. The country is a major supplier of copper to the semiconductor sector. Within ten years, most of the 17 countries that supply copper to the semiconductor industry are expected to face similar drought-related problems. This will put an increasing proportion of the copper supply at risk. It is estimated that by 2035, at least 34% of the copper supply on which global semiconductor production relies will be vulnerable to drought.

It is therefore urgent for semiconductor manufacturers and buyers to strengthen the resilience of their supply chains. Although companies are already taking steps, and according to PwC’s Global Investor Survey 2024, 68% of investors believe that companies should do more to mitigate risks in their chains, additional efforts remain essential.

Measures against drought

Copper mining companies are responding by investing in new technologies such as desalination plants to maintain their water production. They are also trying to use water more efficiently and are focusing on reuse. In countries such as Chile, initiatives have already been launched to combat drought in this way. At the same time, semiconductor manufacturers are starting to take the risk of climate change more seriously. They are seeking alternative raw materials and developing more efficient designs, for example, by producing more compact circuits and diversifying their suppliers to reduce their dependence on a single region. Recycling and circular models are also increasingly being used to make better use of raw materials.

It is important for companies first to identify where climate risks occur in the chain. These risks can then be addressed by, for example, reducing dependence on a single raw material, investing in collaboration with suppliers, and implementing measures that make the entire supply chain more resilient to climate disruption.

Lynne Baber, Deputy Global Sustainability Leader at PwC, emphasizes that companies that identify their vulnerabilities are better equipped to develop strategies that protect their financial, operational, and reputational value. According to her, smart adaptation to climate change not only offers protection, but also new opportunities for innovation, agility, and leadership in an increasingly unpredictable world.