We come across all kinds of interesting projects around automation and digitalization during the year. As far as we are concerned, the autonomous tractor developed by the Dutch company AgXeed is certainly one of them. This vehicle should allow farmers to work more efficiently and sustainably. We spoke with Peter Hendrix, Sales & Operations Director at Phact. This OutSystems partner was responsible for the development of the application and the underlying platform.

The agricultural sector is probably at the top of very few people’s lists of the most innovative sectors. This is not entirely justified, we have come to conclude. In recent years, we have already seen a number of IoT projects pass by at trade fairs run by major players such as Bosch and Oracle, among others. Now, there’s also AgXeed. With their AgBot, this party promises complete autonomy when cultivating the land. This will make the agricultural sector, which will also become primarily data-driven for farmers, ready for the future, is the idea. That is absolutely vital for this sector, in order to be able to deal with issues such as the growing population, stricter regulations from governments, and to work in a more sustainable way.

What is the AgBot?

Even though it may not look like one, the AgBot essentially is a tractor, like the ones that have been used in the fields for a long time. You use it to perform tasks that can also be done with a traditional tractor. However, it doesn’t really look like a tractor as we are used to. This is, of course, primarily due to the fact that there is no driver and therefore no cabin. There are also some differences in terms of other hardware. Below you can see several pictures of the AgBot, and the specifications, which unfortunately are in Dutch. We did reach out for an indication of the price of an AgBot, but didn’t get one.

Phact and OutSystems to develop the platform

In the development of the AgBot, AgXeed itself is taking care of building the equipment. Since it has to drive autonomously over the fields, this also involves the necessary software development. This is done by OutSystems partner Phact.

For an autonomous tractor, you don’t just grab a standard software package off the shelf. It requires customization. That is the specialty of Phact, says Hendrix. In order to get to where we are now in two years’ time, the development environment also needs to be able to can handle such a speed of development. The OutSystems low-code platform is used for this purpose. As Hendrix puts it in our conversation, “Phact makes everything custom by default, OutSystems helps us to deliver custom work quickly and cost-effectively.”

Front-end as the biggest challenge

The most visible thing about what Phact has built in collaboration with AgXeed is of course the front-end. This is the application you use to control and program the AgBot. AgXeed had quite a few requirements in this area, we learn from Hendrix. “UI/UX development goes pretty far outside the box,” he indicates. That was the biggest challenge of the project so far. It all had to look exactly like the rest of AgXeed’s environments, with fairly specific JavaScript and HTML5 requirements. OutSystems itself has been a great help, by the way. This is a special and beautiful project, also for the supplier, so they were happy to free up some extra time for it.

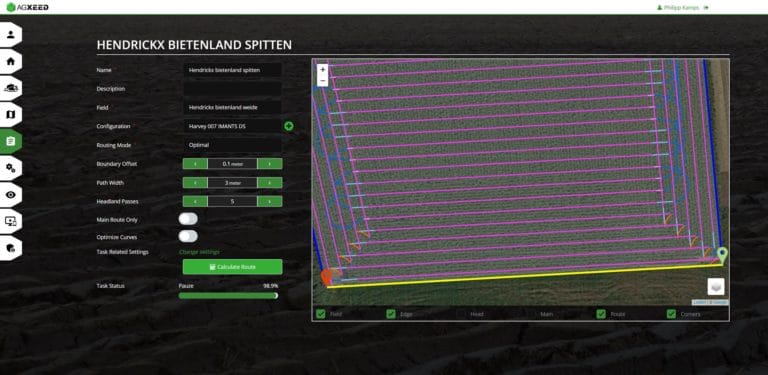

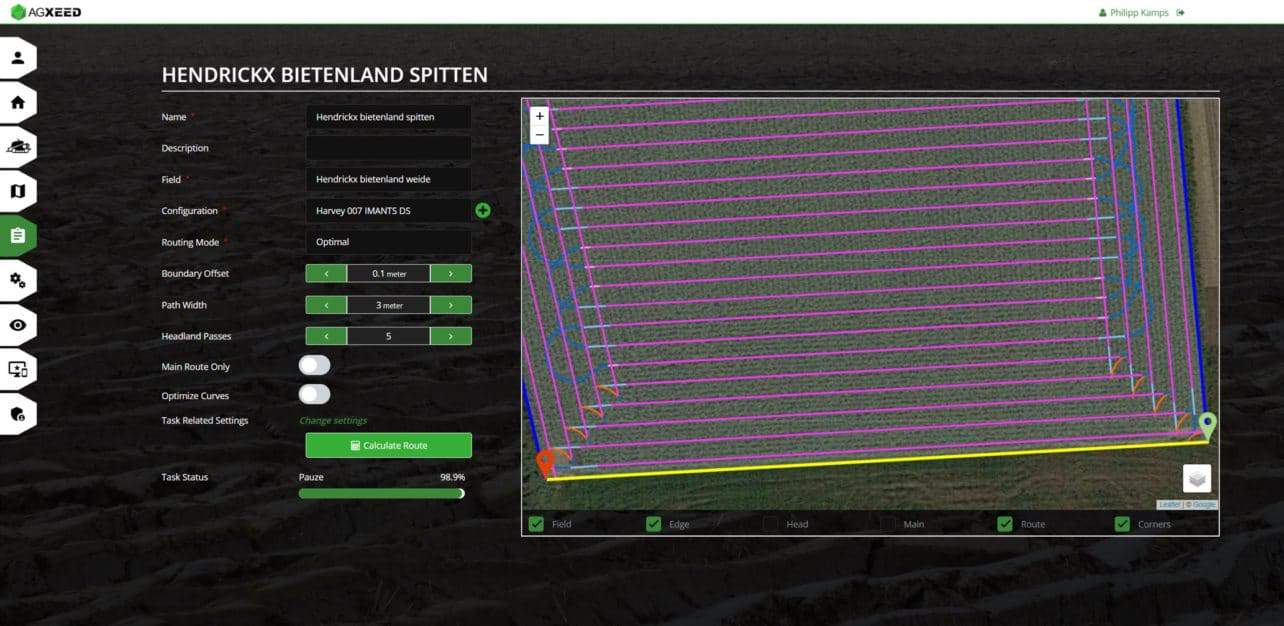

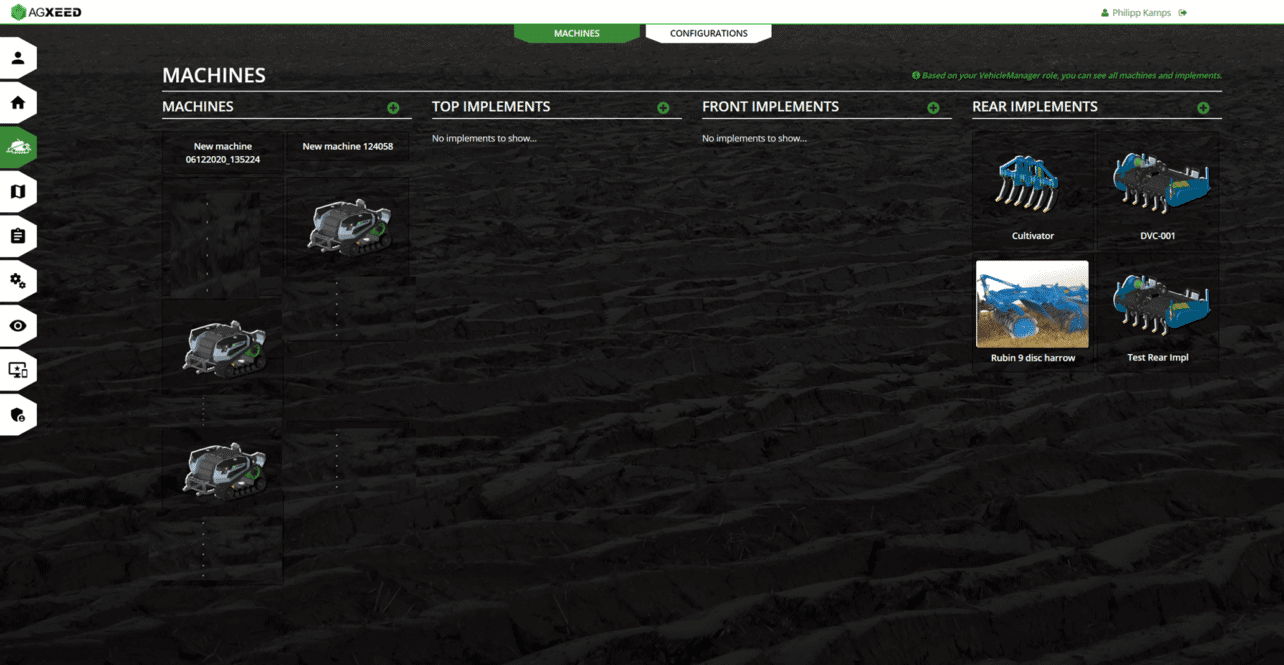

Below you can see some screenshots of the application that Phact built for AgXeed. With this application, you program the AgBot in quite some detail. You key in what you want to do, by choosing for example the tools you are going to use (for ploughing or sowing for example). You also indicate here whether extra weight should be put on the AgBot as a counterweight. Once you have entered everything, a path calculation follows. After this calculation, you deploy it to the machine. The machine is driven manually to the field in question, by the way. At this time, it may not yet be driven on public roads.

Optimizing operations

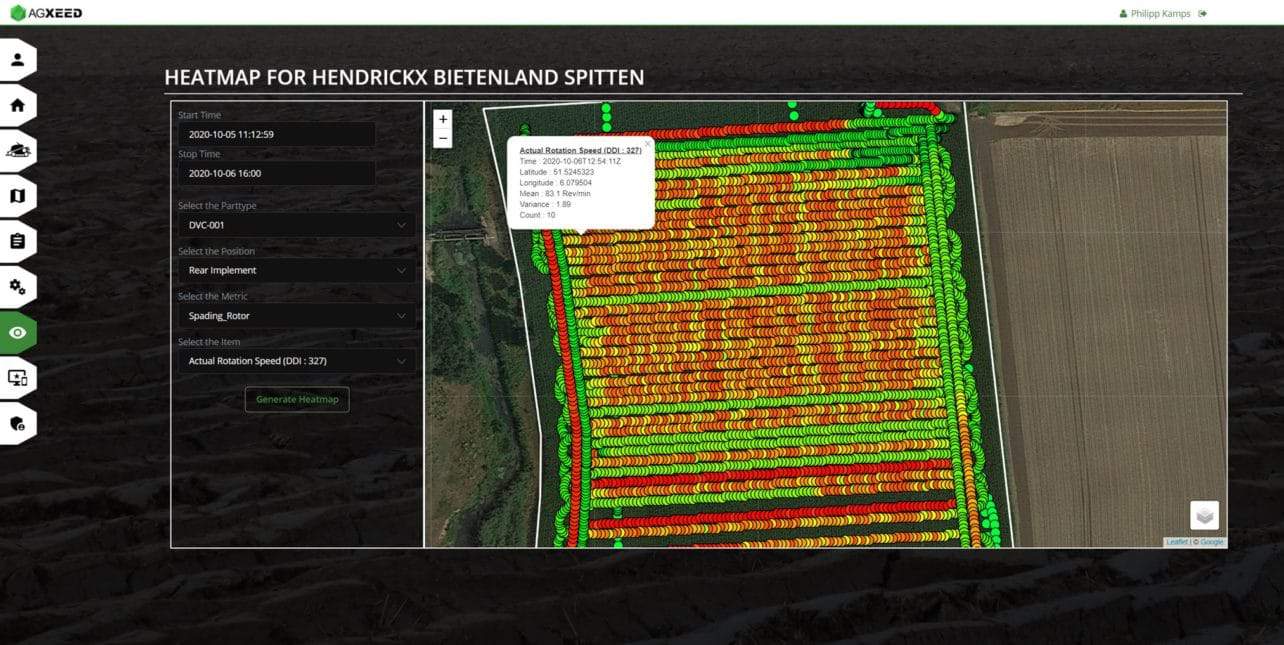

The purpose of the AgBot in itself is quite simple, as Hendrix summarizes: “Ultimately it’s about optimizing the workflow to have as little movement in the field as possible and do everything as efficiently as possible.” This may not seem very complicated at first glance, but practice shows that there is still a lot to be gained in this respect. “We recently managed to reduce the total distance driven on a field to about 10 percent through a clever optimization in the algorithm,” he gives as an example. This not only has to do with the specific route you take on the field by the way. The sensor data coming from the AgBot also plays a role. By optimizing the torque on the axle, for example, you can make significant gains.

Much more than an application

If you want to add this kind of intelligence, then just building an application is not enough. You also need an underlying platform. Phact developed that for AgXeed as well. “We built in a complete .NET module that takes care of routing, among other things,” he indicates. This module also integrates into the platform as a whole.

With the development of the .NET module, it is still not finished, though. After all, IoT data is also transferred between platform and machine (both ways). Phact also built a module for this. This IoT data architecture is set-up in Azure. It makes it possible to collect data and extract valuable insights from it. The aim of this is not only to make the AgXeed equipment function better now, but also to maximize its performance in the future. Or in the terms used at Phact: it provides both hotpath streaming analytics and deep coldpath big data analytics. In this way, it should be possible to get the maximum business value from the platform, equipment and data. Phact has linked this environment to the OutSystems environment through REST APIs.

Asked about the added value of OutSystems in the project so far, Hendrix is clear: “A big advantage of OutSystems is that it makes rapid prototyping possible, while still allowing you to develop an application and platform down to the pixel.” In this project, they have had to rely relatively heavily on developing pieces of code themselves, partly because of the .NET module with route planning, but that goes very well with the low-code environment of OutSystems, he points out.

Living project

You can’t think of a project like this, which Phact has now been working on together with AgXeed (and to some extent OutSystems itself) for over two years, as something with a beginning and an end. “This is not something you build, deliver and then leave behind,” in Hendrix’s words. A project like this is actually never finished. Just a little bit smarter algorithms, for example, are already making gains, as we’ve seen. But that doesn’t mean that it will have the same result everywhere. There are differences in soil types, crops and so on. So it will always have to remain a rather dynamic process, with a bit more project management than usual.

Many possibilities (and a future)

Apart from what has already been built now, there are of course various integrations with the platform to (eventually) consider. The obvious thing to do, for example, is to create a link with ERP systems. Then, based on sensor data, you can immediately see which parts need to be replaced or repaired. If we think a little further, there may also be added value to be gained from a link with opendata systems via a platform such as that of Esri. Especially if 3D mapping will take off as predicted, we can imagine that this could also provide benefits for a platform such as that of AgXeed.

Asked about future integrations, AgXeed proposes a link with Farm Management Information Systems (FMIS). This integration could link application maps for fertilization or crop protection to route planning, for example. The ‘sustainable’ software developed by Phact, which minimizes the production of waste in the form of, for example, extra development hours, should continue to play an important role in this.