Foxconn is one of the largest partners of HPE, the originally Chinese company that assembles HPE servers. Customers put together a fully customised server. Such an order is made by Foxconn, and HPE then delivers the server. An industrial Internet of Things (IIoT) application has been developed to make this process more efficient and faster.

Recently, we were guests at the opening of the HPE Europe IoT Innovation Center in Geneva. Here, together with partners, we will examine which IoT solutions can be applied in different industries. The fact that HPE is now opening a special IoT lab for this meow and that there will be more focus on it, but not that it is new for them. During the opening, several partners of HPE were present to tell how they already cooperate with HPE. These stories from partners were fairly concise. Therefore we decided to delve a little deeper into what exactly has been developed and applied in Foxconn’s case, in order to still highlight one of those IIoT solutions.

Server market almost completely custom made

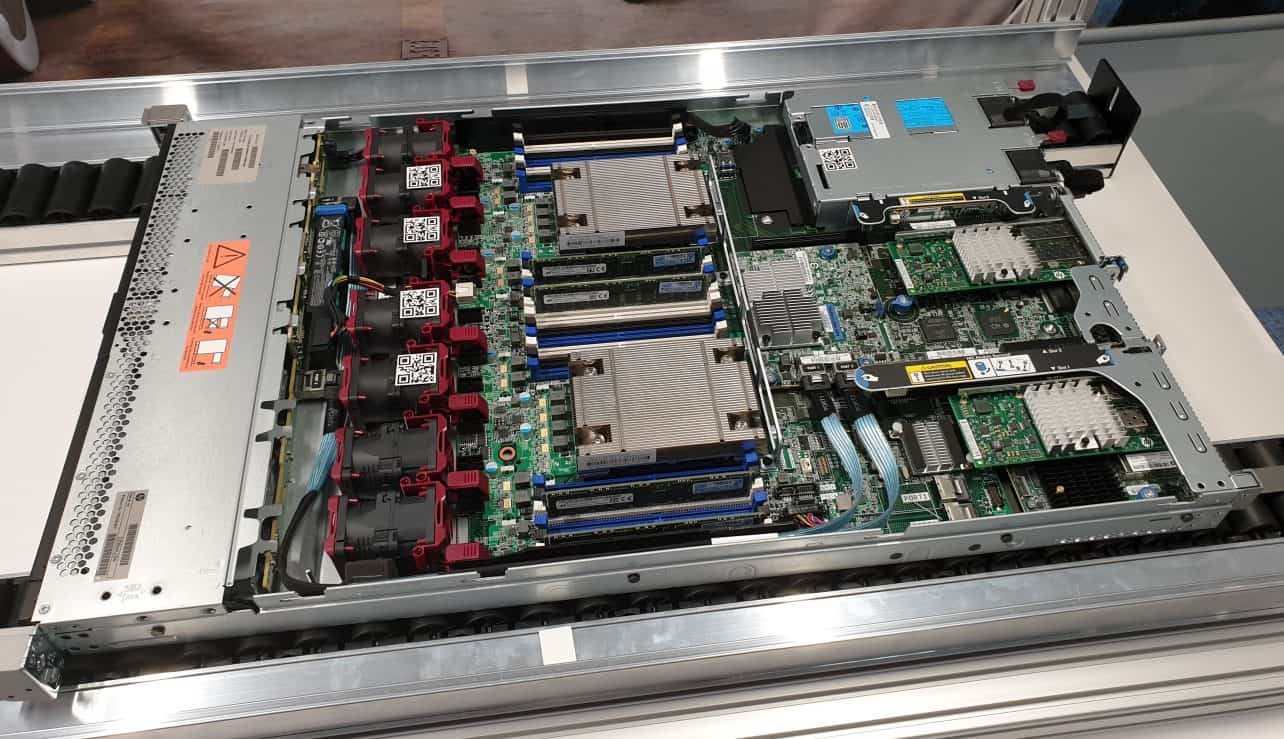

A few years ago, companies like HPE got away with simply offering a number of standard configurations for servers. These were then taken into mass production and delivered to all the different customers. In the meantime, the market has changed considerably, and the demand for standard solutions has almost dried up. Customers want to customize their servers. It is up to them to decide which processor, how much working memory, which RAID card, what kind of storage, and so on. This means that almost every server that leaves the band is quite unique.

Foxconn is the partner of HPE to assemble and deliver the servers. The fact that HPE has opted for this is no surprise. Foxconn provides production or assembly services for almost every technology company in the world. For example, Foxconn also takes care of the production of Apple and Samsung smartphones. Everyone in the Netherlands and Belgium has products that come from a Foxconn factory.

Unique server compositions create extra challenges

With the changing market demand for custom-built servers, the challenge for Foxconn has increased considerably. With every order, the company has to select and bring together the right components, ensure that the servers are assembled in the right way and meet all quality requirements. This may sound simple, but it’s not. Many parts in servers are very similar, and only the type number can often indicate which product is in them, while the performance of the parts is very different.

Checking the assembly process is also becoming more and more difficult because each server has a different configuration. On top of that, people quickly overlook something. If a server is delivered with problems, HPE has to provide support and possibly someone at a customer location. In the worst case, a replacement server has to be delivered. This causes delays that the customer is not happy with.

Checking server assembly is now done through artificial intelligence

HPE and Foxconn sat down together to discuss how they could improve this process. With the help of a startup specialized in machine learning that HPE recently acquired, the company was able to check the assembly of servers more easily. This was done by using artificial intelligence (AI). With this technology, the company has developed an IIOT solution. HPE now has the certainty that every server that rolls off the tape is properly assembled and will not cause problems immediately. This sounds simple, but a whole process has preceded it.

How does this IIoT solution work?

HPE and Foxconn examined the entire assembly process and adapted it to make it as efficient as possible. Although Foxconn already uses robots in some factories for the production of certain goods, this is far from being the case with servers. This is still done by people, and people make mistakes. So it has to be checked somehow and corrected where necessary.

At the start of the assembly, the housing is provided with a QR code and serial number. This is linked to the order where all components are listed. The server then goes through the entire assembly process, and all the components that belong to this server are assembled.

When the server is completely ready, it goes through a checkpoint that is equipped with the new IIoT solution. This is a conveyor belt with a framework above it that is equipped with six cameras. These cameras photograph the server from all angles and holes. The system analyzes these photos immediately, and the employee is immediately shown whether the server has been approved or rejected, along with the reason.