Start Campus is in the process of building a very large data center in a unique location in Portugal. For its liquid cooling system, it uses parts of existing infrastructure from the region’s more polluting past, combined with a closed loop inside the data center. Schneider Electric invited us to to visit the site and find out all about it.

Sines in Portugal probably does not ring a bell with many people. Connoisseurs of ports and seafaring may know that it is one of the few seaports in Europe (besides Rotterdam) where even the largest ships can moor and where you can find massive storage tanks for oil. History buffs may know it as the city where explorer Vasco da Gama came from. Tourists may also have passed through, as there are some beautiful beaches. Otherwise, this town of less than 15,000 inhabitants does not really capture the imagination.

Start Campus puts Sines on the map

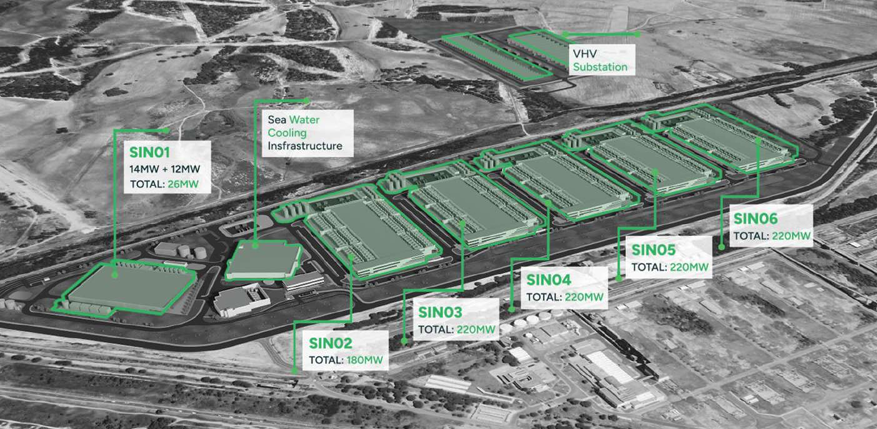

From now on, however, Sines is a place to keep an eye on if you are active in the world of IT, specifically in the construction of data centers. Since October 2024, Start Campus has been working on the first phase of a data center that most definitely captures the imagination. It is a 1.2 GW data center. The first (and smallest) 26MW section, called SIN01, will be fully operational next year. This will be followed by five more buildings, all larger than SIN01, for a total of 1.2 GW. Start Campus is also building a VHV (Very High Voltage) substation on the site to supply power to the entire complex.

Below you can see what the final result will look like:

The new Start Campus site will be Portugal’s largest data center. According to the builder, it will be powered entirely by renewable energy. This makes it a flagship project for Portugal in more ways than one. The country wants to position itself more and more as an important hub in the data center and connectivity world. It has a surplus of green (renewable) energy and plenty of space to build data centers, according to representatives of Start Campus. With subsea cables arriving from multiple directions, it is also an interesting location in that regard. In this way, it wants to compete with countries such as the Netherlands as a “Gateway to Europe.”

The new Start Campus data center complex will not only be the largest in Portugal. It is also one of the few in Europe to have secured more than 1 GW of grid power. Portugal has officially designated it as a project of national importance. In addition, it claims a PUE of 1.1 once it is fully operational. In practice, it is virtually impossible to achieve a lower figure. You can read more about how Start Campus is achieving this later in this article.

The role of Schneider Electric

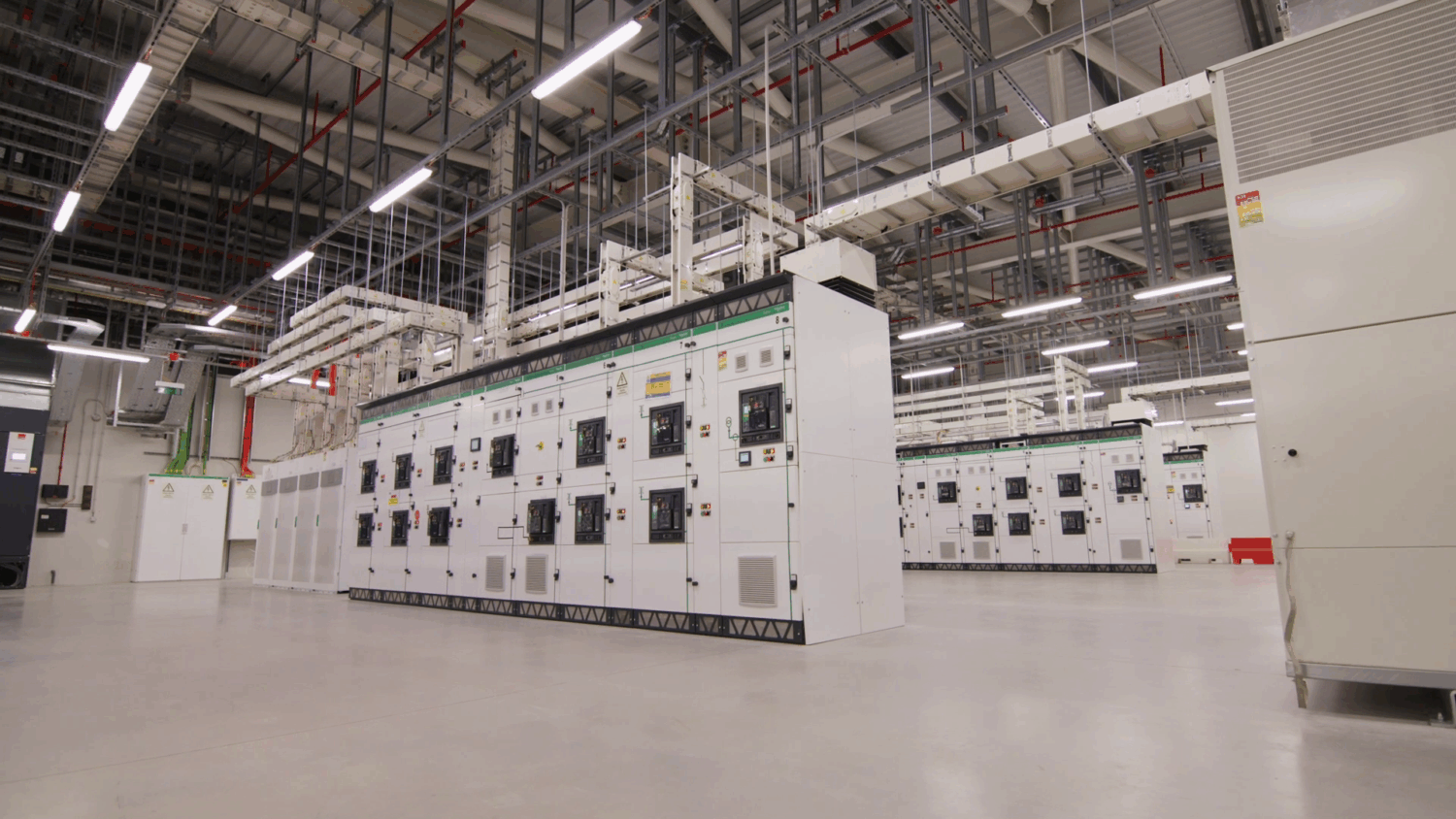

Schneider Electric invited us to come and see SIN01 for a reason. It supplies a considerable amount of equipment and software to Start Campus.

SIN01 uses an extensive package of solutions from Schneider Electric’s EcoStruxure portfolio. By combining data from Schneider’s infrastructure solutions with real-time insights via the EcoStruxure software, Start Campus says it can achieve a high level of operational efficiency. This is particularly important in view of AI workloads, for which Start Campus is explicitly developing this new data center.

The new Start Campus data center does not only use Schneider Electric software. It also uses the Schneider Electric Galaxy VX UPS, one of the company’s top models. In addition, Schneider Electric is supplying the switching equipment and MV and LV distribution systems for the electricity. Looking at EcoStruxure, the specific focus is on the implementation of EcoStruxure Buildings Management, Energy Management, and Power Monitoring Expert. This software provides real-time insights in areas such as automation and cybersecurity. The latter has certainly been an important topic in OT environments recently.

Focus on sustainability

Finally, Start Campus has received support from Schneider Electric’s Sustainability & Consulting Services in developing a Power Purchasing Agreement strategy. This will ensure that Start Campus can purchase 100% renewable energy for the new data center. This is important for modern data centers, which are under increasing pressure due to their ecological footprint.

The focus on sustainability is not new. Schneider Electric is also working with other companies such as Digital Realty to reduce Scope 3 emissions in data centers. Last year, the collaboration with Digital Realty focused on extending the life of equipment and applying circular principles. This collaboration with Start Campus is much more fundamental than that.

Article continues below the box

Liquid cooling sometimes involves “experiments at scale”

The fact that Start Campus is building the necessary flexibility into the cooling system is not only to be able to properly regulate the temperature of the water that flows back into the sea. Liquid cooling as a whole is still in the early stages of development. We discuss this during our visit to Sines with Andrew Bradner, GM and SVP Cooling Business at Schneider Electric.

In general, liquid cooling is not new, of course. However, it is only since the AI boom that it has really become a topic that is not only being discussed but is also attracting more and more concrete interest. While it is possible to cool 100kW/rack with air cooling (and this is certainly being done, according to Bradner), it is becoming increasingly clear that this is not the future, especially if it has to be done on an ever-larger scale.

However, one of the challenges of liquid cooling is that it is currently quite unclear what the correct temperature is. Every manufacturer has its own values. This makes it difficult to set a fixed temperature in a modern, heterogeneous data center environment. The result is that, understandably, data centers choose the safe route and take the lowest common denominator as the starting point.

To be clear: ideally, you cool with liquid that is as warm as possible. This simply results in higher efficiency. Bradner calculates that every degree you can raise the temperature yields a three percent gain in efficiency (or capacity, depending on your preference). That may not sound like much, but in a data center the size of the one in Sines, it quickly adds up to a lot.

If you keep the above in mind and factor in the highly dynamic modern AI workloads, the calculation becomes even more complicated. Bradner acknowledges that the industry still has a lot of work to do. He readily admits that this will not be easy, but it has to be done. That’s why Bradner mentions the “experiments at scale”.

A standard is needed

Ultimately, it is clear what needs to be done. Standards for liquid cooling must be established. If you ask ten suppliers what the capacity of a CDU (Coolant Distribution Unit) is, you will get ten different answers, according to Bradner. Not only does the temperature of the water/liquid play a role here, but also the impact that filters have on the performance of a CDU. For example, a supplier may claim a capacity of 1.3 MW for a CDU, but 30 percent of that capacity may be lost as soon as a filter is installed.

Customers are also increasingly asking for proof based on real tests to back up suppliers’ claims. But how do you test equipment on the scale at which it is used today? Not everyone can do that. Bradner naturally sees this as a clear opportunity for Schneider Electric. In his view, there is only a select group of candidates capable of carrying out this type of large-scale, real-world testing. Furthermore, the well-known ASHRAE organization is now also working on developing standards. That will help too.

Fully liquid-cooled, using seawater

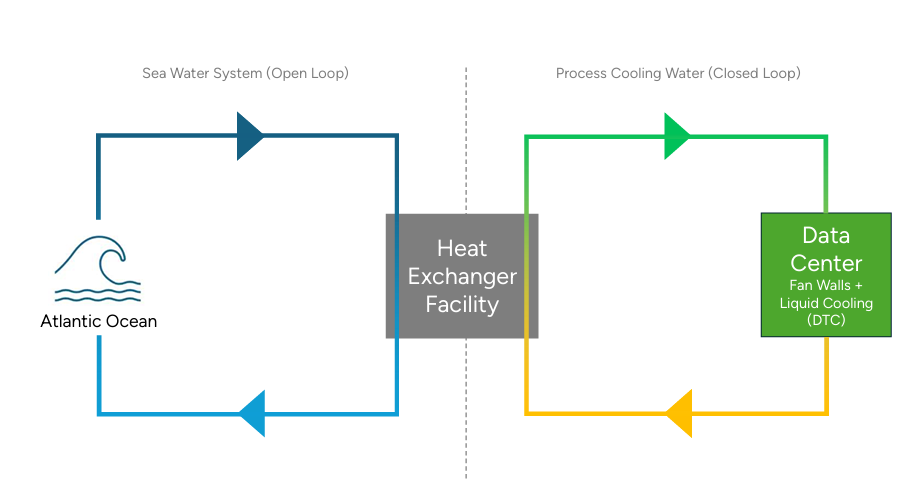

The size of the new Start Campus site in Sines is remarkable in itself. However, in our opinion, this is not the most remarkable aspect of SIN01 and the buildings that will follow. That is the fact that Start Campus will not only cool it entirely with liquid via a closed loop liquid cooling system, but also that this liquid will be cooled in turn with seawater.

Location by the sea, next to a coal-fired power plant

Start Campus chose its location near the sea for a reason. It needs the seawater to cool the liquid that flows through the data center. The system is almost complete and is expected to be ready very soon. At present, cooling is still provided by cooling towers by the way. These are needed as a backup and are currently running to dissipate the heat.

Start Campus is using existing infrastructure to connect to the sea. The data center is located right next to an old coal-fired power plant, which was operational from the 1970s until 2021. The builders of that plant also built infrastructure to provide cooling capacity for the coal-fired power plant. Specifically, this involves an inlet and an outlet. Start Campus will make use of this. The pumps and pipes are already in place for SIN01, but some additional work is needed for the next buildings.

Below, the photo on the left shows the data center from the air. At the bottom left is the inlet for the seawater. This is where the structure you see in the photo on the right is located. The blue pumps and pipes are for supplying seawater to the data center.

How does cooling with seawater work?

Basically, cooling the liquid that cools the racks in the data center is fairly simple, although the practical implementation is, of course, far from easy. The liquid flows past cooling plates in het heat exchanger on one side and the seawater on the other. The two streams are completely separate form each other. The seawater that enters the system through the inlet is filtered before it passes the expensive titanium plates, but never comes into contact with the liquid that runs through the pipes in the data center and the chemicals it contains. The only thing that happens to the seawater is that it warms up and flows back into the Atlantic Ocean.

Below is a simplified representation of how the system in Sines works:

The materials for the seawater system have, of course, been chosen to withstand the salt content of the seawater. Furthermore, the setup is also partially redundant. Of the five pumps, only three are in operation at any given time. This is to allow maintenance of the pumps and the connected circuits without having to shut down the entire system.

According to Start Campus spokespeople, this will all happen within the set parameters. The water at the outlet can’t get too warm. They can continuously finetune how much water goes in through the inlet and out through the outlet each second. This is important because the temperature of the seawater is not the same throughout the year, but the number of degrees by which it may deviate is (3 degrees). In total, it should be possible to send around 1.4 million cubic meters of seawater past the plates every 24 hours.

SIN01 is innovative in several ways

All in all, SIN01 (and the upcoming expansions) is an interesting case in several ways, in our opinion. Start Campus shows that the construction of very large data centers is certainly still possible, but that it is sometimes necessary to look beyond the standard construction ideas. The combination of 100 percent renewable energy, cooling with seawater and the reuse of existing infrastructure certainly sends a signal to the market. With increasingly stringent PUE requirements, it may well be worthwhile to explore alternatives such as this when looking for a location for a data center.

Whether Start Campus will actually be able to deliver on all its promises with SIN01 (and the expansions) remains to be seen, of course. No doubt everything has been very well thought out. However, both AI and liquid cooling are subject to rapid development and change. At the end of the day, it is a system of communicating vessels. If something goes wrong somewhere, it will have an impact on the entire chain. In any case, there seems to be sufficient bandwidth built into the cooling infrastructure. In a while, when everything is up and running, we will know how it works in practice.