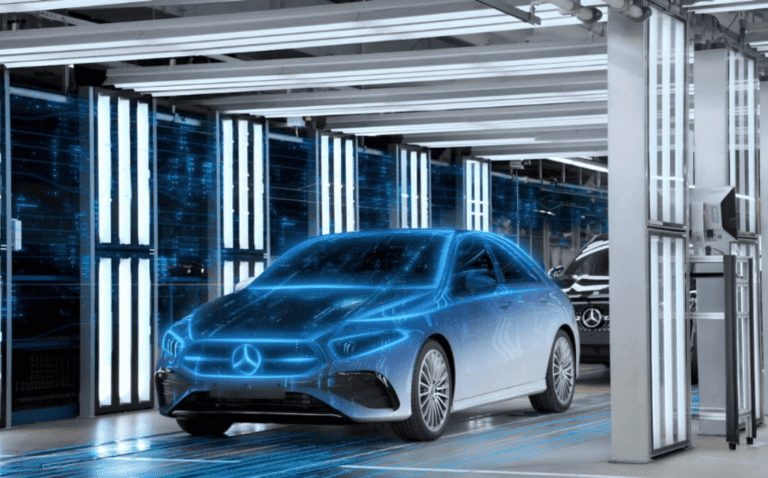

Nvidia is partnering with Mercedes-Benz to optimize car production. By creating a digital twin of the entire manufacturing and assembly process, the German car brand can figure out exactly how to work as efficiently as possible.

Mercedes-Benz hopes to create a blueprint for more than 30 factories worldwide with the help of the digital twins. It aims to prevent defects, coordinate better with suppliers and set up assembly halls 50 percent faster. Facilities in Rastatt (Germany), Kecskemét (Hungary) and Beijing are cited as the first to apply the new technologies. In the Hungarian plant, a complete digital twin is said to have already been set up.

The digitization of a work process is not new: digital twins occur everywhere and in the automotive world, for example, in Formula E races. With a digital twin, a company attempts to create a digital representation of reality that is as realistic as possible in order to detect errors and make improvements to work processes in advance. Likewise, Nvidia and Mercedes are no strangers to each other: in 2020, Nvidia already helped the automaker develop “software-defined” vehicles. This involved new vehicles with advanced soft- and hardware, extensions of self-driving functions and other updates. Thus, Mercedes’ “digital first” approach is broader than just revamping factories.

Savings thanks to AI

There’s one major headache Mercedes hopes to alleviate as much as possible with digital twins: having to stop production. Predictive analytics with the help of AI can ensure that maintenance happens on time. In Rastatt, Germany, AI already monitors sub-processes that are being tested in a pilot, where energy savings of 20 percent are said to have been achieved.

The digital simulations run on Nvidia’s Omniverse platform. An introductory video from Nvidia about this platform might suggest that it is primarily suited for 3D modeling and game design, with its original purpose having been assisting Pixar in making animated films. However, the platform offers a wide range of linked applications for professional purposes. As seen here, it allows a company like Mercedes-Benz to digitize and further test cars and their manufacturing. Together with Nvidia, Mercedes-Benz envisions a future where factories can operate more flexibly and have as little downtime as possible.

Also read: Digital twin shows golf insights at The Open