Nearfield Instruments has secured 135 million euros in a series C investment round. The money will help accelerate the chip company’s further growth. It has already secured Samsung as a customer.

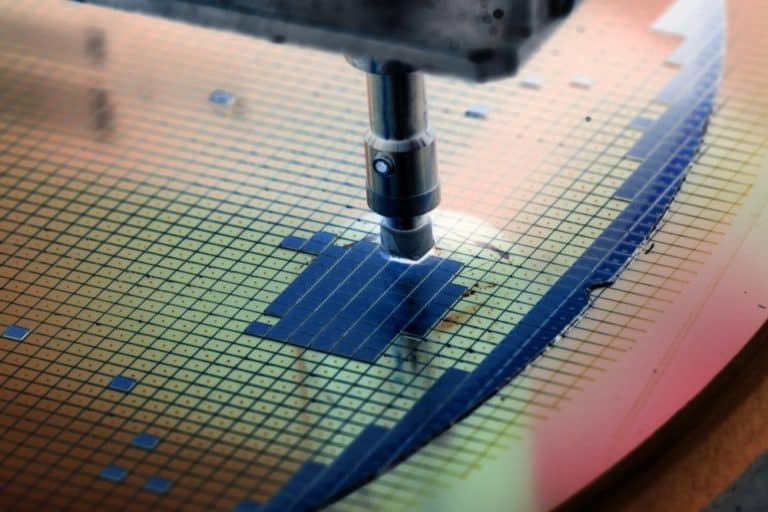

Nearfield was founded in 2016 as a spin-off from TNO. The Rotterdam-based company sells machines that check the build quality of modern chips, a specialization known as Process Control metrology. This application is becoming increasingly important as the feature sizes in chip technology have become atomically small. In addition, the design of modern chips is now mostly three-dimensional, with stacked pieces of silicon to further improve performance.

Walden Catalyst, a U.S. investment firm, led the Series C round. Founding Managing Partner Young Sohn stated: that advanced chips are “the key pillars for global innovation and growth.” “The next generation of semiconductors will be driven by advanced lithography and 3D integration, with smaller features, deeper trenches and tighter tolerances.” For that reason, it is imperative to have better measurement equipment in-house.

Previously, Nearfield Instruments raised 17.5 million euros (2021) and 27 million euros (2023). In late 2023, the company also received government funding for further development, with the Dutch cabinet making 230 million available to Nearfield, NXP and ASML.

Tip: Maker of chip metrology equipment Nearfield heading for 100 million euro investment

Samsung deal

Recently, Nearfield managed to bring in South Korean giant Samsung as a customer. Nearfield’s measurement technology, called Quadra, survived an “intensive evaluation period,” as Bits & Chips recently described it. However, Samsung and Nearfield have been working together to detect defects for five years. Yet the tech was only deployed by the R&D division, and Samsung only recently began deploying Nearfield’s devices for mass production.

Nearfield describes Quadra as a nondestructive measurement system that allows a high throughput and resolution. Speed, in particular, is essential for practical deployment within the chip industry, as each time-consuming part can easily cost thousands of dollars per hour.