Zebra Technologies is investing heavily in machine vision. Partly through targeted acquisitions, it has now invested more than a billion dollars in this technology. We spoke with Jan Naessens and Ivar Keulers about the innovations within this business unit and the possible applications in the automation of factories, warehouses and logistical processes.

Zebra Technologies, best known for collecting and sharing data using barcode scanners and printers, has initiated a strategic change of course in recent years. Jan Naessens, Machine Vision Manager at Zebra, together with Ivar Keulers, Machine Vision Engineering Lead, guided us through the developments this business unit (and Zebra as a whole) has undergone.

“Zebra has traditionally been known for collecting and sharing data. But factory automation is constantly evolving,” explains Naessens. This presents Zebra with both challenges and opportunities. “Warehouses employ fewer and fewer people. These people are also increasingly difficult to find. This also means that organizations need fewer wearables. And that is a problem for Zebra,” he outlines the challenge for the company.

However, where challenges loom, opportunities also arise. Zebra saw this too, particularly in machine vision. It actually began with the introduction of cameras for fixed scanning. “During that transition, we realized that we could also get into machine vision,” according to Naessens. Zebra is serious about this, as is evident from the fact that it has already invested more than a billion dollars in it.

Strategic acquisitions strengthen machine vision portfolio

Part of Zebra’s investments in machine vision have been directed towards acquisitions. One of the first was the Polish company Adaptive Vision, which, according to Naessens, recognized early on that AI would play an important role in machine vision. “Adaptive Vision has developed an AI that does not need to be trained. It works with pretrained models on many fonts,” he says. The latter is very valuable when checking labels on medicine packages with the help of OCR (Optical Character Recognition), among other use cases.

A second strategic acquisition was Matrox Imaging from Canada. This company was and is strong in frame grabbers (among other things), technology that converts analog images to digital. “Matrox was crucial to our development,” says Keulers. After the introduction of the first fixed scanners in 2021, there were still a number of limitations, including the maximum number of megapixels that the cameras could have at the time. The limit back then was 2 megapixels. Not because there were no sensors available with a higher resolution. They certainly were available. However, these also caused higher heat production and required more computing power. The addition of the Matrox portfolio solved these problems, among others.

The most recent addition is Photoneo, a company specializing in 3D cameras. “In addition to AI, 3D is an important driver of innovation in manufacturing,” says Naessens. “Photoneo is very strong in 3D cameras, which helps us offer a more complete solution.”

Applications in the connected factory

Machine vision plays a crucial role in what Zebra calls the connected factory. According to Keulers and Naessens, Zebra’s solutions have four main applications. Firstly, Zebra cameras literally give robots eyes, in 2D or 3D. It is also possible to use machine vision for quality control, such as detecting the absence or presence of parts, inspecting color or finding defects.

A third application for machine vision in the connected factory is contactless measurement. Thanks to machine vision, it is perfectly possible to measure things such as distances and sizes. The fourth application mentioned by Naessens and Keulers is identification. This can involve barcodes, something that Zebra has traditionally been very strong in. However, it can also involve OCR, which we briefly discussed above. This is where Adaptive Vision acquisition comes into play.

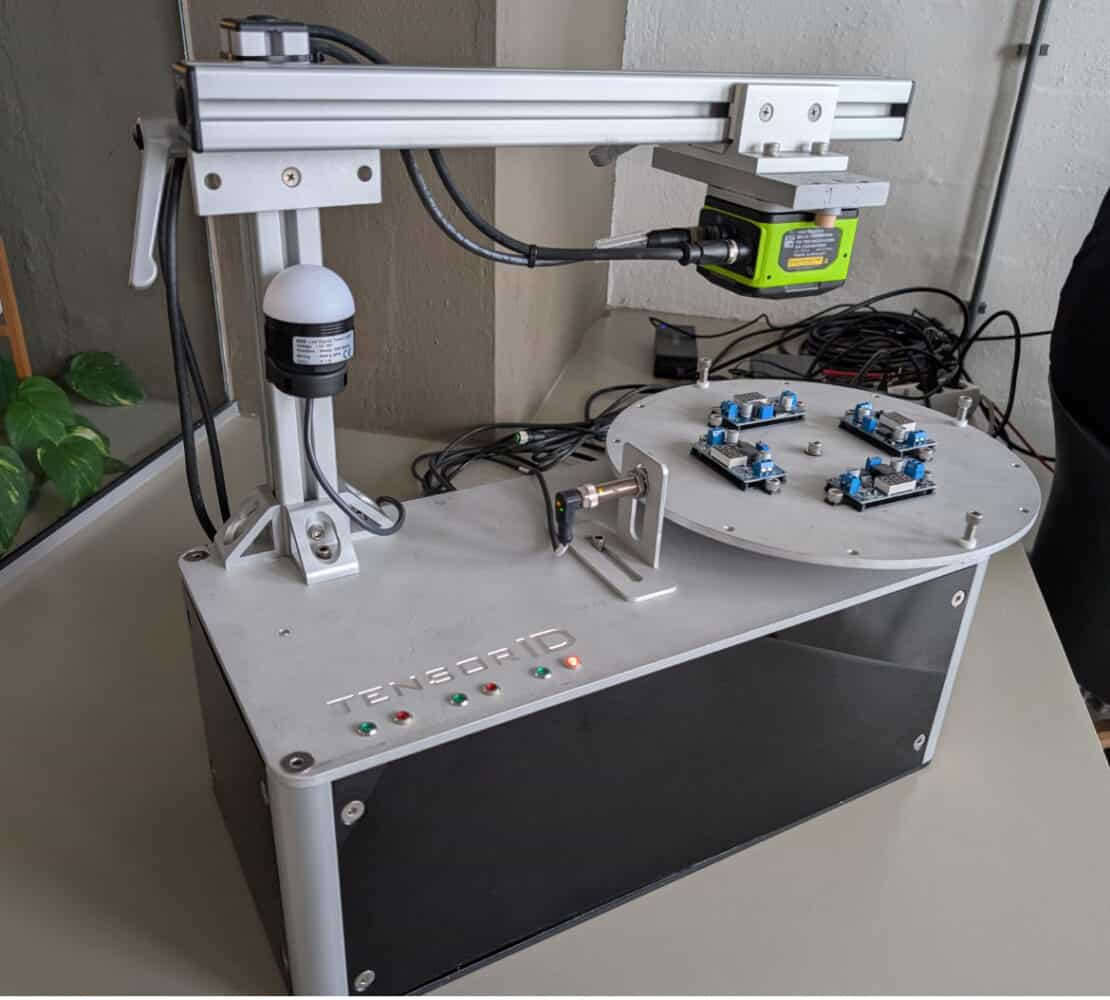

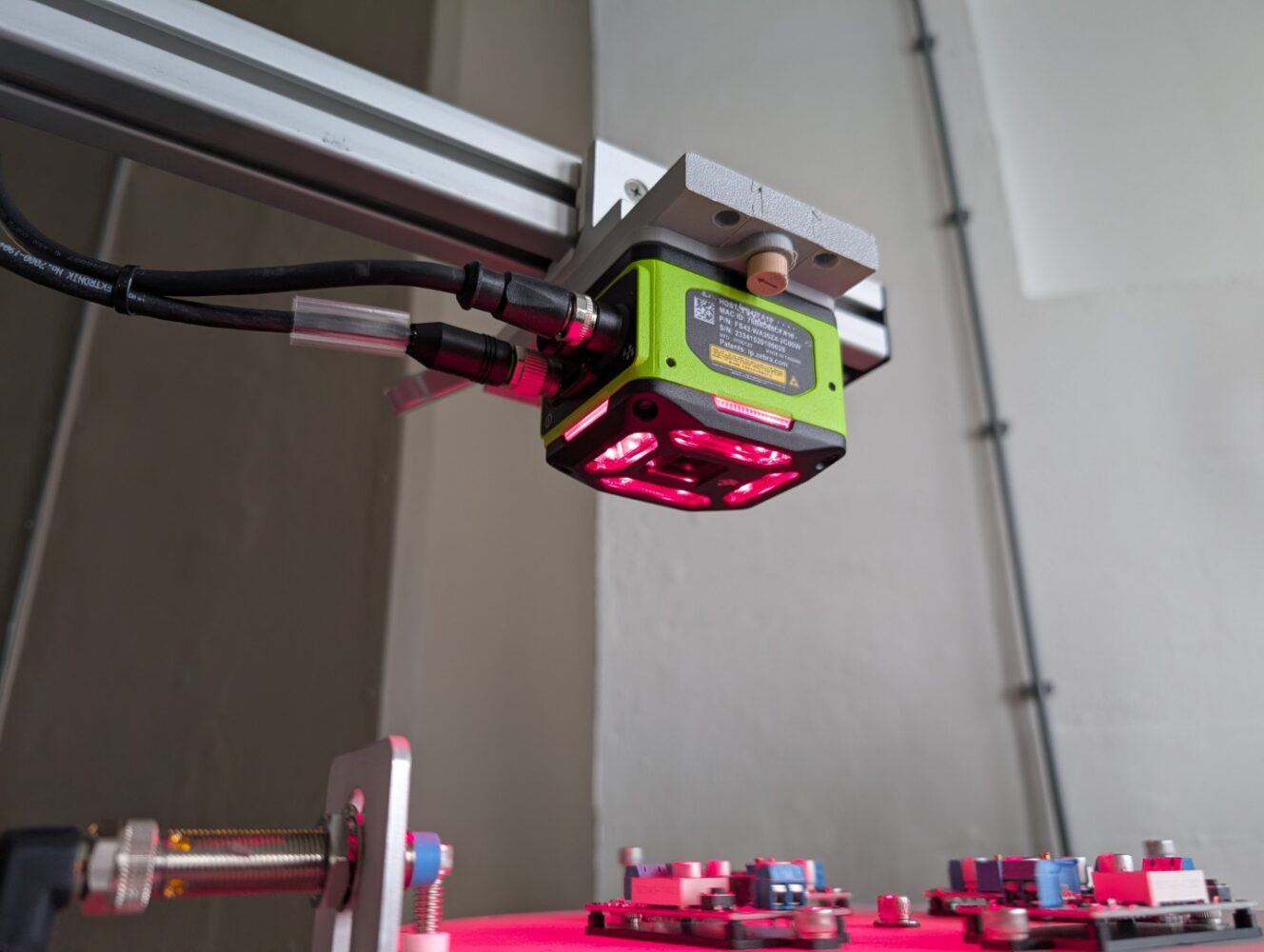

Zebra NS42 Smart Vision Sensor

The meeting with Zebra, where we spoke to Keulers and Naessens, was not just about theory and strategy. We also got a demo of two new products that fit within the machine vision story.

Firstly, there is the NS42 Smart Vision Sensor. You can see this as a further development of the fixed scanning range. The NS in the product name stands for Neural System, which implies advanced capabilities. And that is certainly the case, as we hear from the gentlemen from Zebra. The NS42 combines OCR with deep learning and anomaly detection. Focusing specifically on anomaly detection, the NS42 can classify and identify scratches and dents, among other things. The NS42 can also detect missing parts on products.

The special thing about the NS42 is that Zebra has not trained it to detect defects. That is to say, it is not trained with images of defective products. The AI models, which run on the NS42 on a Neural Processing Unit (NPU), are trained with products that do not show defects. Anything that deviates from this is classified as defective. The advantage of this is that there is no need to build a huge database of specific defects. Of course, there is still a range of what is classified as good. Customers still have to decide that for themselves. However, that is much easier to achieve than trying to capture all possible defects in a model, we suspect.

Zebra FS80 Fixed Scanner

The second new product is the FS80. That is a Fixed Scanner. This is a product from the line that started it all for Zebra in 2021 when it comes to machine vision. In June of that year, it launched the first so-called FIS (Fixed Industrial Scanning) camera, the FS42. At the time, the technology was still quite premature, but it is now at a good level, Keulers says.

A fixed scanner does what the name suggests. It is a scanner/camera that users place in a fixed location. It then scans everything that passes by in a specific process. During the demo of the FS80 that we are given, it is clear that the scanner works very accurately up to several meters away. Even when we pass a barcode at high speed in front of the camera, the device scans it flawlessly.

The FS80 Fixed Scanner has several interesting technical features. For example, it uses a so-called hidden strobe. This is lighting that switches on and off like stroboscopic lighting, but the FS80 does this so quickly that it is not visible to people, even those who are sensitive to it. However, it is still substantially different from continuous lighting. That is, the LEDs still flash, and boost to a higher brightness than is possible with continuous lighting. Naessens tells us that despite this boosting, the LEDs also last longer than when they are continuously on.

Keulers emphasizes another striking feature of the FS80. It has audio, to give a clear confirmation that a scan has been successful. According to him, no other supplier of this type of device has this.

Finally, Keulers cites a practical example of the use of a fixed scanner. “Zeelandia [a Dutch supplier of bakery ingredients, ed.] uses an FS40 in combination with forklift trucks, making hand scanning superfluous. That saves a considerable amount of money, about 20,000 euros.” In addition to the costs, there is something else at play here. There are more and more restrictions on using a hand scanner on and from a forklift. In Australia, drivers have not been allowed to scan from a forklift at all for some time now for safety reasons. More countries are expected to follow suit. With a solution like the one Zeelandia uses, organizations are already prepared for this.

Zebra wants to offer a complete solution

Machine vision may be a (new) stand-alone business unit, but it is also part of the greater Zebra whole. It does not want to be known as a pure hardware supplier, but wants to evolve as a provider of integrated solutions. “Zebra’s strength is that we can do everything,” Naessens emphasizes. “Not just scanning, not just machine vision. Zebra can help on multiple fronts to make work more efficient.” It is clear that machine vision plays an important role in this.