Although Lithium Extraction (DLE) can reduce the environmental impact of lithium mining, there are objections to the technology.

Lithium forms the basis of car and smartphone batteries. It’s one of the world’s most sought-after raw materials. Often, Lithium is mined in large open-pit sites and evaporation basins, which have a major impact on the environment.

Several companies, including General Motors and mining giant Rio Tinto, are currently investing in new Direct Lithium Extraction (DLE) technology. This technology is intended to reduce the size of extraction and evaporation processes, which can reduce the footprint of a production environment.

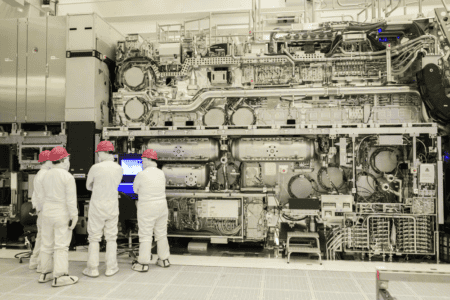

Specialists are investigating production methods that separate lithium from pumped brine using filters, membranes, ceramic ‘beads’ and other equipment. These production methods can often be housed in a small warehouse, allowing the size and impact of lithium factories to be reduced.

Objections to DLE

Despite its pros, there are objections to the technology. Firstly, current DLE uses a lot of water: upwards of 10 tonnes for every single tonne of lithium. Though this can be overcome by desalinating brackish lithium brine, that process is still in development.

Secondly, DLE’s applicability is limited. It simply can’t be deployed everywhere. Depending on the mining location, a specific technology has to be used.

In short, DLE is promising, but not fully there yet. In any case, it’s the first step towards a more sustainable lithium mining method.

Tip: Northvolt produces its first fully recycled battery cell