The volume of data that a company creates increases significantly every day. Without a doubt, one of the most interesting developments that this brings about is the great opportunities it creates. Process mining, a relatively new discipline, shows that data really is the new gold. It is comparable to an MRI scan, but of a company’s processes instead of a human body. This way, you get enough insight to optimize those processes. The technology behind this is interesting and complex at the same time.

In fact, we can see process mining as a method of being confronted with the facts about data in the first phase. Almost everyone knows that the amounts of company data are huge. Even the data of one process are quite complex. In itself, this is quite logical, because usually an employee only handles part of a process.

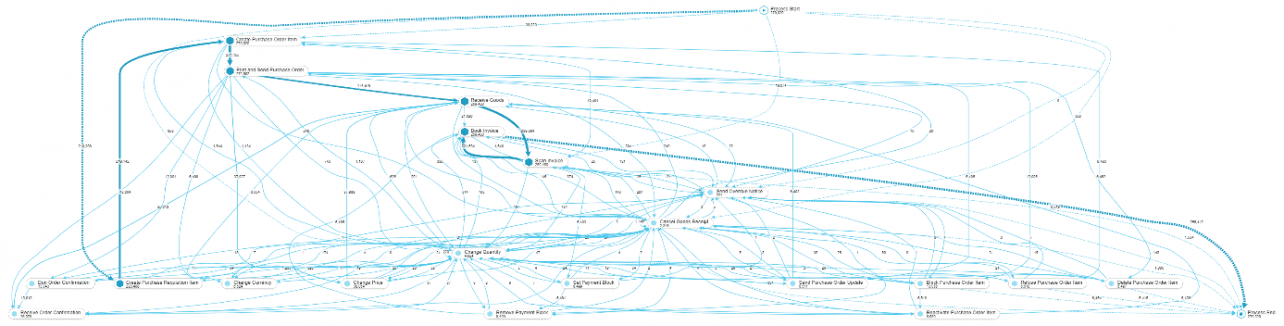

By visualizing all variants within a process, you really see the difficulty of the entire process. In addition, it is immediately clear that efficiency can be increased a lot. In the first instance, this seems like a real confrontation, as the software from process mining vendor Celonis shows below.

Anyone who is actually ready to untangle this big pile of process spaghetti will find that simplicity can be created out of the complexity. After all, the purpose of process mining is to remove bottlenecks from a business process. By really optimizing the processes with the help of process mining, costs can be cut considerably.

Transparency instead of complexity

When we speak to Lucas van den Ingh, Celonis’ Head of Solution Engineering Benelux, we find out that process mining is relatively (!) easy. The above complex mess of processes does not require weeks of training, but it does require a new way of thinking about processes. It often takes some time to get into your head, something that takes about a day, before you can see all kinds of new opportunities and possibilities.

Moreover, we already indicated that the image above visualizes all variants within a process. For example, you can also choose to show the three most common variants within a process. Visually, this looks much simpler. It is likely that finding deviations in a process is a lot more difficult than that, which is probably a more common goal of Celonis users – but that’s a matter of switching to the different variants.

Example provides clarity

In our conversation with Van den Ingh we also get an example of how the detection of these anomalies works. It analyses a procurement process within a large organization. The example assumes that 13,500 purchase orders with price changes have been created. This may seem high, but in practice, this is how it works. All kinds of factors cause a price to fluctuate up and down, such as the volatile value of raw materials.

With process mining, you can dive deep into your data to find the actual reason for the price changes. In the example of Van den Ingh it concerns a material for lamps, which specifically makes 8,000 lamps a cause of the change. The new price list had not been implemented within the organization, which means that in every invoicing cycle, an error occurs. The organization, therefore, loses five minutes per order. 8,000 times five minutes is, of course, a huge loss of time and money. It is this kind of bottleneck that is detected by process mining. Sometimes, fixing a problem of this kind just requires some very minor adjustments, such as creating new price lists.

Implementing processes is relatively simple, but can take a long time

In this case, we are mainly talking about what makes process mining possible. To be able to analyze a process, some work and technology are needed. It all starts with setting up a process. Celonis has a marketplace for this, in which we find processes that are very specific. In itself, this shows that process mining is a technology that lends itself perfectly to real enterprise organizations. The processes are not only made for well-known solutions such as SAP and Salesforce, but also for procurement software parties such as Coupa and SAP Ariba. Such parties offer real software for organizations with tens of millions or billions in revenue.

Once the desired process has been found, a switch can actually be made to installing such a process. For the simple processes, three steps have to be completed. First of all, a connection to the system from which the data comes is required. Such a connection can be made via a cloud API. To retrieve data from an on-premise Oracle or SAP system, for example, the connection must be made through the network, which is discussed in more detail below.

Next, the process must actually be configured. Here you arrange things like the date from which data is needed, converting values from dollars to euros and reloading data at night. If everything is to your satisfaction, then the data extraction can start. This step is the most time-consuming since now all the desired data are actually extracted from a system. A large organization simply has a lot of data in, for example, an SAP system, which means that it can take one to several days to retrieve all of the data during an initial data load.

Extracting data from every system

After hearing about this implementation process, we wonder if Celonis has any problems with data extraction. Van den Ingh states that in general, people are always able to access the data, although this can be a challenge. The simplest method is to extract the data from a cloud solution from a SaaS vendor. Then it’s a matter of sending data from cloud to cloud, since Celonis itself is completely cloud-based. With these cloud APIs, mutual communication is possible.

In addition, Celonis has specific connectors for many common systems, so you know how the SaaS solution stores data. Data is written in many different ways. Not only does this make it difficult to find data, it also makes it difficult to extract meaning from the data. For example, a field can contain one or two data, which simply means ‘approve’ or ‘reject’. Linking these meanings to the numbers yourself is difficult, the connectors do this effortlessly.

However, the story of data collection becomes more difficult when local systems are in use. To retrieve data from on-premise environments, you need to get to the underlying database to get the most out of it. Depending on how open such a system is, it can take a long or short time to extract the data. And then there is also the need to give meaning to the data.

Nevertheless, Van den Ingh states that the collection of data has so far been successful with any modern system. After all, in recent years, everything has been stored in order to guarantee traceability and audits, among other things. As a result, there are always data that make process mining possible. Data extraction is only a problem when old systems from the 1980s were used. At that time, transactions were not recorded, and a lot was done with pen and paper. In theory, only then do you run into problems, but in practice, it is often of little use to use this very old data for process mining.

The entire process transparent, regardless of which solutions

It is also worth mentioning that a process can use data from various SaaS solutions. For example, it can happen that the purchase order is created in SAP itself, the data is extracted from an invoice by means of Invoice Capture Software, and everything else is processed in SAP Ariba. Ultimately, there are so many different variants within a process, which can all be analyzed with process mining.

It is this whole methodology that has made process mining so big. The link with the different systems is there to be able to move on to going through and analyzing a process, which is also referred to at Celonis as process discovery and process analytics. Recently, the company has also added a new component to make the user a little more alert. The action engine can be seen as a personal assistant who autonomously analyses data. Because the engine detects deviations in the processes and also predicts them by means of machine learning, the entire Celonis process mining story needs to be further improved. As a result, the process mining software will continue to develop sufficiently.

Proven technology needs to increase range

So we’re not so much concerned about how process mining looks like technology, but rather about actually extending the range. To be honest, Business Intelligence as an analytics method, for example, is currently better known and more accessible than process mining. In that respect, there is still room for improvement.

However, Celonis has proven that large enterprise organizations choose their software. Van den Ingh is proud to have AkzoNobel, Siemens, Shell and Vodafone as customers. These are typical parties that Celonis has to rely on, because they have countless large processes where there are bottlenecks, for example in customer service and production. If they use process mining, they can save millions. Van den Ingh mentions Siemens and Vodafone as companies that have already identified millions in savings through process mining. Let’s hope for Celonis and the business community that many more will follow suit. In any case, we will continue to follow developments closely here at Techzine.