Vertiv already offers an extensive range of modular data center solutions and is now adding the MegaMod CoolChip to its portfolio. This liquid-cooled prefabricated unit is suitable for retrofitting existing data centres or building entirely new facilities. It is specifically designed to run demanding AI workloads, because of course it is.

Vertiv’s new prefabricated modular (PFM) unit is fully customizable and suitable for the platforms of all leading suppliers of AI workloads. Depending on customer requirements, the solution can be expanded at will. It supports up to hundreds of kilowatts per row, up to several megawatts.

Data centers are naturally energy-hungry. Vertiv, however, promises a smaller carbon footprint than traditional building methods through both advanced liquid cooling and advanced power infrastructure.

Enough water for GPU powerhouses

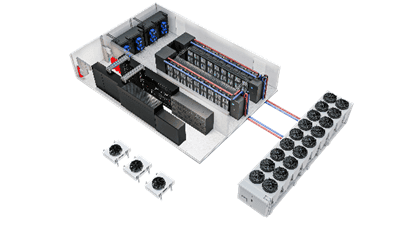

The system’s most notable feature is its high-density liquid cooling. The MegaMod CoolChip unit uses direct-to-chip cooling to prevent the CPU and GPU powerhouses inside from getting too hot when performing their workloads. Efficient heat dissipation is also provided for components not powered by direct-to-chip heatsinks. The balance between liquid cooling and air cooling is matched to the AI workload platform’s design to ensure optimal efficiency.

Vertiv boasts that the MegaMod CoolChip combines various technologies, thereby reducing the time required for AI infrastructure implementation by 50 percent. For example, it integrates different systems via racks with built-in cabling and high-density rack power distribution units (rPDUs) from Vertiv itself. Customers can also house their own selected integrated racks from other vendors within the prefabricated units.

Everything to be assembled on-site

Naturally, there is room for surge protection and efficient power distribution alongside the rack. Here, too, Vertiv provides its own solutions, such as an uninterruptible power supply and the PowerNexus solution. This involves tight coupling into a single block connected by internal rails, which saves space, cable material, installation time, and costs.

As mentioned, this prefabricated system is completely modular. The housing and all its components can be assembled on-site like a high-tech Ikea DIY-kit. The solution is also available in skid-mounted units that simplify transportation and installation. All components can be used for new facilities, retrofits, and expansions. Vertix assures users that all components are integrated in a clean and controlled factory environment to reduce risks during assembly and testing.

Building blocks

PFM data centers are on the rise because as the standardization of data centres increases, it becomes possible to make their building blocks larger as well. These include both standard modules and customized, specific components.

Prefabricated modular construction is faster than building everything on-site from scratch. It is also more scalable because modules can be easily connected. Furthermore, the costs are lower because of the use of standard components.

Also read: Enter the age of the wooden data center; Vertiv introduces TimberMod